08/17/2021 10:00:00 CEST, Reutlingen Since market entry in 1995, Manz has established itself as an esteemed provider of end-to-end automation solutions in the display industry | From hardware to software – automation systems from a single source allow easy integration | Modularization of the systems for quick and easy extensions of production lines and capacities | Customers benefit from more efficient processes, lower manufacturing costs and competitive end products

Manz AG, a globally active high-tech engineering company with a comprehensive technology portfolio, has just delivered its 200th robot handling system for the biggest G10.5 display vacuum coating tool. For more than two decades, Manz has been providing innovative automation solutions along the entire display value chain in Asia. In the process, Manz is constantly developing these automation systems tailored to customers' needs in line with the latest production requirements, demonstrating "best-in-class" high-tech engineering in software and hardware again and again. Manz systems are particularly impressive due to their high quality, reliability, and ease of integration into existing processes.

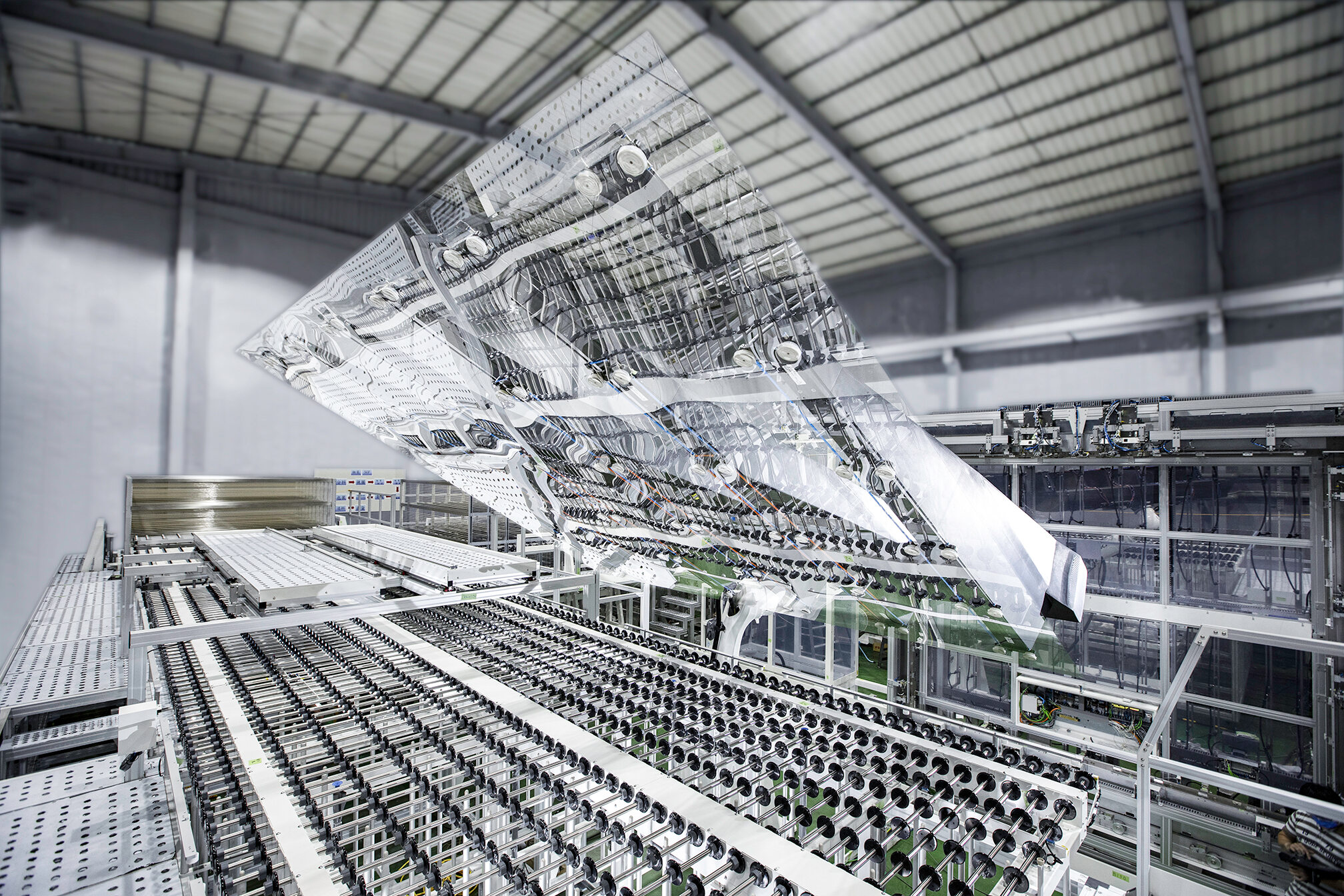

With its many years of expertise in the development of hardware and software, Manz offers its customers individual solutions from a single source: from production planning to robotics and mechatronics, including optical inspection systems, to comprehensive drive and control systems. In particular, the carbon gripper system developed by Manz ensures maximum stability combined with low vibration and low weight, which virtually eliminates the breakage rate when handling the glass substrates, which are up to 2940 x 3370 mm in size and ultra-thin at 0.4 mm.

In partnership with display manufacturers, Manz's solutions ensure that complex production processes run more efficiently, manufacturing costs are reduced, and end products can be offered competitively. The modularization of production equipment and software allows both a simple and quick expansion of existing production lines and capacities as well as a problem-free conversion of the lines or complete process changeover.

Martin Drasch, CEO of Manz AG, comments: “In the field of automation systems for display manufacturing, we have gained a strong market position over the past years, as of date we have delivered more than 2,800 robot handling systems for all kind of display sizes. We have succeeded in this not least due to the close, partnership-based relationship with our customers; from the development phase to joint commissioning and individual service packages, they rely on our support and expertise. With our many years of experience in wet-chemical processes, we are proven experts in the field of display manufacturing up to Generation 10.5. The enormous increase in displays in modern cars in particular, but also the continuing demand for consumer electronics products such as smart watches, laptops or wearables, is leading to an ever-greater need for displays. With our technology and process experience, we are very well positioned to benefit from these growth trends in the display market in the future.”

The carbon gripper system developed by Manz ensures maximum stability combined with low vibration and low weight

The carbon gripper system developed by Manz ensures maximum stability combined with low vibration and low weight