12/01/2021 12:00:00 CET, Reutlingen Received orders from BMW and TE Connectivity, among others | Strategic partnership concluded with GROB WERKE | New image video summarizes the offer for the automotive industry

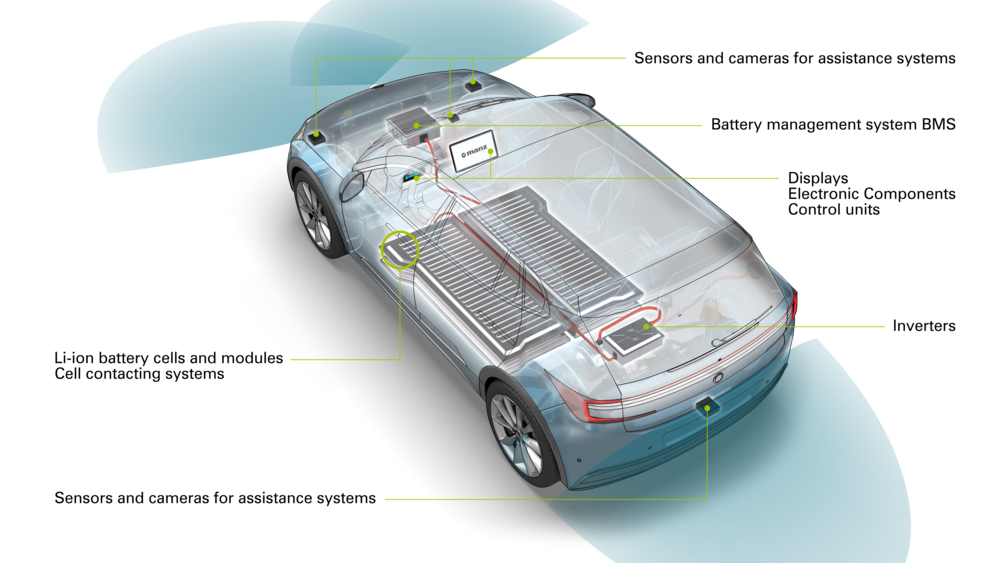

The automotive industry and electromobility are strategically important sectors and important growth areas for Manz AG. In recent years, Manz AG has consistently expanded and optimized the portfolio range for OEMs and their suppliers. The globally active high-tech mechanical engineering company now offers, among other things, production solutions for various components in the fields of automotive electronics and electric powertrains. The focus here is on system concepts for the efficient production of

li-ion battery cells and modules, cell contacting and battery management systems as well as inverters.

The results for 2021 in the field of e-mobility are quite impressive: a US manufacturer of electric vehicles was won as a new customer at the beginning of the year. Among other things, Manz AG was able to convince with its expertise in the field of laser welding. The proven and precise processes for the safe welding of li-ion round cells to a battery module based on the BLS 500 laser platform in combination with the modular assembly platform LightAssembly ensure decisive competitive advantages for new customers in terms of effectiveness, scalability and product safety.

Further milestones in 2021 were the cooperation agreement with GROB-WERKE GmbH & Co.KG as well as the expansion of the cooperation with the long-standing customer and automotive supplier TE Connectivity. Thanks to the partnership between GROB and Manz, the two companies can offer the production processes that are crucial for electromobility for the manufacturing of li-ion battery cells and modules, from coating the electrode material to pack assembly, from a single source and fully integrated. The follow-up orders from TE Connectivity in the course of the year underline the competence of Manz AG as a manufacturer of automated production systems for components of the electric powertrain - in the case of TE Connectivity, powerful and reliable cell contacting systems.

With the order from the BMW Group at the beginning of November to set up a highly integrated pilot production line for li-ion battery cells at the Parsdorf site near Munich, Manz was able to win one of the leading German automobile manufacturers as a customer. The order includes systems for coating the electrode material and for assembling the li-ion battery cells.

The BMW Group's commitment underlines the role of Manz AG as a central partner of the automotive industry in realizing the mobility transition. The high-tech machine manufacturer not only offers its customers an innovative, modular production and assembly platform, but also an enormous amount of automation know-how that has grown over decades. Manz AG can fall back on a comprehensive process library here. The advantage for customers: They can quickly and directly fall back on stable, standardized and tried-and-tested machine and system concepts and thus get their product on the market faster.

“The changes in our mobility through networked vehicles, semi-autonomous and autonomous driving, intelligent safety systems and fully electric drives require numerous leaps in innovation. An essential key to success will be how agile and flexible OEMs and suppliers set up their production systems in order to be able to adapt to rapidly changing requirements. Our production concepts and production systems are modular and therefore extremely flexible. Together with our partners, we offer solutions from individual machines for laboratory production to systems for small series production through to fully integrated series production from a single source,” says Martin Drasch, CEO of Manz AG.

The company has visualized the range of competencies and the role of Manz within the automotive industry in a new image film:

Manz Portfolio for the automotive industry

Manz Portfolio for the automotive industry

Cell contacting system for prismatic li-ion battery cells

Cell contacting system for prismatic li-ion battery cells