09/25/2012 09:08:00 CEST Manz AG has entered the market for vacuum-coating systems used in the production of crystalline solar cells with a fully automated system for front- and back side coating. The VCS 1200 PECVD system coats the front and back sides of a vertically positioned silicon wafer with a throughput of up to 1,200 wafers per hour.

- Fully automated system for front- and back side passivation of crystalline solar cells

- Manz covers all necessary process steps required to manufacture highly efficient PERC cells with its own technologies

- Significant increase in efficiency of monocrystalline and polycrystalline solar cells

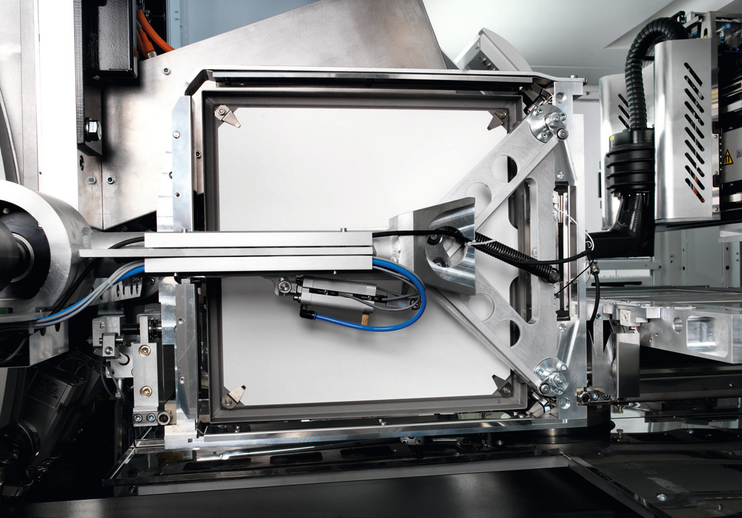

Manz AG has entered the market for vacuum-coating systems used in the production of crystalline solar cells with a fully automated system for front- and back side coating. The VCS 1200 PECVD system coats the front and back sides of a vertically positioned silicon wafer with a throughput of up to 1,200 wafers per hour. Passivation is achieved through plasma-enhanced chemical vapor deposition (PECVD), and can also be integrated into existing production lines.

The VCS 1200 stands out thanks to creating the best possible layer properties, both in silicon nitride as well as aluminum oxide layers, and the ability to manufacture the typically used layer stack in one step. In addition, the system simultaneously cuts production costs, and this plays a key role in making the production of the next generation of highly efficient solar cells profitable again. This step is made possible thanks to the VCS 1200’s high-performance plasma source (patent pending), which in addition to optimal layer properties, also contributes to the high stability of the coating. In addition, the process is carried out without shading thanks to the innovative Manz Coating Carrier System (patent pending). This means the pin marks known from other manufacturers’ systems that result from mechanical fixing, as well as the associated loss of quality, now belong to the past. The new process concept and the vertical position of the wafer during the coating process both ensure that the surface is extremely homogeneous. This also prevents defects that can arise in conventional systems as a result of particle deposits before or during the coating process.

Extensive Range of Technologies for the Highest Level of Efficiency

Passivating the back side of the solar cells with aluminum oxide has two major benefits. First, the layer reflects the photons in the long wavelength range back into the cell, and in doing so, increases the cell’s light efficiency. Second, aluminum oxide increases the lifespan of the charge carrier generated in the cell and, as a result, leads to an increase in current and voltage. Both aspects increase the solar cell’s efficiency.

Back side passivation of PERC (passivated emitter and back cell) solar cells is carried out in three steps. First, one side of the wafer is polished using a wet-chemical process. Afterwards, it is covered with an aluminum oxide coating and a covering layer of silicon nitride using PECVD. Finally, the dielectric layer stack is opened with a laser in order to create a local contact with the back side of the wafer. Manz covers all of these process steps with technologies developed internally. Furthermore, the company is the only supplier with the ability to offer its customers additional efficiency increasing processes, such as the Manz One Step Selective Emitter or the HAP 2400 high-accuracy printer. As a result, the individual steps are all perfectly tailored to one another, and this leads to a significant increase in both throughput and efficiency in production as well as an increase in the efficiency of the cells.

Profitability for Existing Production Lines

The new VCS 1200 vacuum-coating system was developed by Manz Coating GmbH, which was founded in 2010. According to the General Manager Mathias Höfler, “The extremely short period of time required to bring the system to market is the result of the concentrated technological expertise of the 50 highly specialized engineers employed at our location in Karlstein. With this tool, we are now a supplier of systems for every important technological step in solar cell production.”

Manz designed this system so that it can be easily integrated into existing production lines. The result for cell manufacturers is an outstanding opportunity to once again increase profitability. Dieter Manz, founder and CEO of Manz AG adds: “Everyone knows the difficulties the photovoltaic industry is currently facing, which is why all cell manufacturers need to cut the cost per watt. Our compact PECVD system is the perfect solution thanks to its extremely low investment and operating costs.” Manz will present the new coating system to the public for the first time at the EU PVSEC industry trade show in Frankfurt am Main, Germany (September 25–28, 2012).

Photo 1, 2: Manz increases efficiency of crystalline solar cells with a new vacuum-coating system