06/13/2012 10:14:00 CEST Last year's winner of the Intersolar Award in the category PV Production Technology, Manz AG, will once again exhibit a powerful range of products at the Intersolar in 2012. At booth 380 in hall A6, Manz will present its new wet-chemical silicon wafer processing system for the first time in Europe.

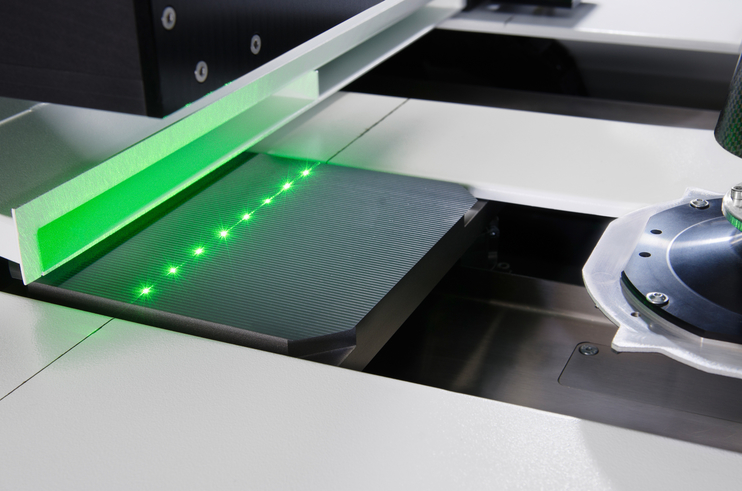

Manz's new IPSG CEI 4800 wet chemical system has a throughput of 4,800 wafers per hour.

- New wet chemical system will be presented in Europe for the first time

- Manz presenting the company as a supplier of complete PV production lines

- "Integrating process steps is key to cutting costs"

Last year's winner of the Intersolar Award in the category PV Production Technology, Manz AG, will once again exhibit a powerful range of products at the Intersolar in 2012. At booth 380 in hall A6, Manz will present its new wet-chemical silicon wafer processing system for the first time in Europe. In addition to its current range of production equipment for crystalline solar cells and thin-film solar panels, Manz will also be presenting its latest developments in CIGS thin-film technology.

Manz's new wet chemical system IPSG CEI 4800 (inline removal of phosphor silicate glass IPSG and chemical edge isolation CEI) chemically removes the highly-doped layer from the back and edges of a silicon wafer and isolates the emitter from the back. In a second step, the remaining layer of phosphor silicate glass on the top side is also removed. The new system has a throughput of up to 4,800 wafers per hour. When developing this system, Manz was able to utilize its long-term expertise in display engineering.

With its wet chemical system for the PV industry and its vacuum coating and texturing systems scheduled for release in the fall, Manz has almost reached its goal of becoming a supplier of equipment for every step of the solar cell manufacturing process. At the same time, with its CIGSfab Manz is the only supplier of a fully integrated production line for CIGS thin-film solar panels that can be operated profitably. Last year the company successfully demonstrated the capability of its CIGSfab by presenting a CIGS thin-film panel with an aperture efficiency of up to a previously unmatched 15.1 percent (equal to 14 percent module efficiency).

"Our customers can only cut their manufacturing costs per watt through the integration of a continuously increasing number of individual manufacturing steps into one system or by optimizing existing production lines", says Dieter Manz, founder and CEO of Manz AG.

Manz's One-Step Selective Emitter, which last year won the Intersolar Award by impressing the independent jury of experts with its outstanding level of efficiency and cost-effectiveness, is only one example of this. This product offers an increase in efficiency while simultaneously cutting manufacturing costs.

The Intersolar is one of the largest solar industry trade shows in Europe, and is being held June 13-15 in Munich, Germany. The organizers expect around 80,000 visitors to the exhibition.

The One Step Selective Emitter was honored last year with the Intersolar Award – the low additional manufacturing costs make it cost-effective after only one year.