08/27/2013 11:51:00 CEST Higher resolution, brighter colors or a better viewing angle – no matter how small or how large a display is, its specifications will be influenced to a great deal by the machinery they are made on. Manz AG as the global leader in wet chemistry tools for TFT-LCD display and touch panel production shows its latest technology at one of the world’s largest industry shows, TOUCH TAIWAN in Taipei from 28-30 August 2013.

- Manz exhibits at Touch Taiwan as world-leading provider of wet-chemistry equipments for TFT-LCD and touch panel production

- Sole provider of touch panel total fab solutions ensuring maximum throughput and yield rate

- Focus on wet chemistry, vacuum coating and automation equipment enables technology leap on customer side

Higher resolution, brighter colors or a better viewing angle – no matter how small or how large a display is, its specifications will be influenced to a great deal by the machinery they are made on. Manz AG as the global leader in wet chemistry tools for TFT-LCD display and touch panel production shows its latest technology at one of the world’s largest industry shows, TOUCH TAIWAN in Taipei from 28-30 August 2013.

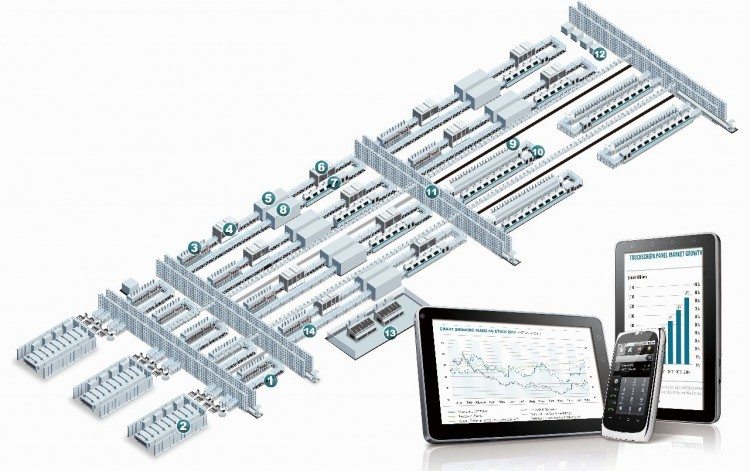

Manz is the only equipment provider who offers total fab solutions for producing touch panels. Eric Chen, President of Manz Asia, identifies four key advantages for its customers: “First, Manz provides not only tools but also process knowledge. We therefore can shorten the time of equipment adjustments significantly. Second, I would mention our outstanding R&D ability. Our tools can be customized to meet client needs through our advanced abilities in component manufacturing and independent design. Third, we have a highly integrated approach in developing and producing sputtering tools and slit coaters. These two machines can ensure the highest coating uniformity and material utilization at a remarkably high throughput and are essential for the sensitivity and performance of final touch panel products. The fourth element of our total fab solution is our highly integrated automation tools to reach economies of scale.”

Manz is also active in the markets for solar-panel and battery manufacturing equipment. Its expertise is based on six core technologies, including automation, laser processes, vacuum coating, printing, metrology and wet chemical processes.

Three questions for Simon Hsieh, Vice President of the display business unit at Manz Asia.

A lot of very prestigious high-tech consumer products are made on Manz equipment. What challenges does it bring for you?

Well, markets are moving fast. That means, we have to move fast as well. Our R&D engineers always need to be one step ahead of the technology hitting the stores for Christmas right now. We offer our customers to start mass production within one month of delivery. We are measured by how stable our equipment works because scale does matter in a global economy; an hour of extra maintenance or even a significant number of faulty or damaged displays cost much more money than a few years ago.

And where is display technology heading?

No doubt, AMOLED and 4K are great to watch. Different technologies will have different advantages – some for the home, some for the road. We always try to imagine the final consumer product and we do this by getting involved as an equipment provider early on alongside our customers. For touch panel, we are proud to say that Manz is the only provider with experience of mass production to offer touch panel total fab solutions for big generation of substrates. We also have to be very flexible and thus, offering a whole range of 0.3mm~2.2mm substrates and production process such as OGS, TOL, G/G, F/G, flexible materials or cover lens.

How does Manz as a manufacturing equipment provider influence prices of displays and touch panels?

To a great extend, I would say. OLED and 4K TV sets are still very expensive. It is on the manufacturing side to bring cost down fast. As a critical equipment supplier, we offer our customers savings in manpower, in materials, in process time. Thus, we considerably decrease their total costs of ownership but increasing production yield. In addition, as our technology continues to evolve we are able to handle 0.3mm substrates to reach the desired features of a panel such as thinner and lighter mobile devices. All these little details add up in a complex process like coating. Be very sure: in two to three years from now, AMOLED and 4K will be affordable for a lot more people – thanks to manufacturing engineers such as ours at Manz.