05/21/2012 09:50:00 CEST New wet-chemical tool based on display know-how to step up integration of crystalline PV production process.

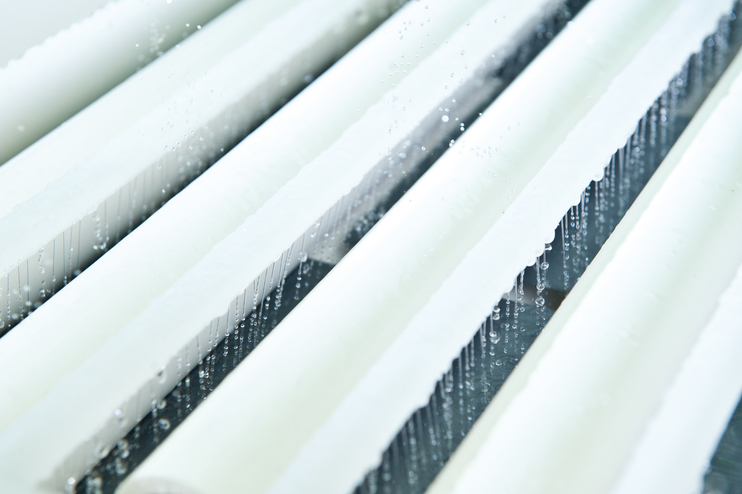

Manz’s new wet-chemical tool IPSG CEI 4800

Hightech-Engineering firm Manz AG introduced new equipment for wet-chemical processing of crystalline silicon solar cells at SNEC 2012 fair. Purpose of the tool named IPSG CEI 4800 is to remove the highly doped layer from the backside and the edges of a wafer and thereby produce a chemical edge isolation (CEI). In a second process step the remaining phosphor silicate glass (PSG) layer on the front side of the wafer that was created during the previous diffusion process step, is removed. “With our new wet-chemical tool we really close the gap in the PV processing chain previously uncovered by Manz. Integrating more and more process steps in a single tool will help our customers to drive down cost per watt”, says CEO Dieter Manz.

As the name of the new tool implies, throughput will be high at up to 4,800 w/h. A newly developed soft sponge roller process concept enables faster inline transportation speeds and ensures at the same time higher process stability combined with gentle wafer handling. “With additional optimization we can even process up to 5,000 wafers per hour”, says Kari Raudasoja, Product Manager in Manz cSi division. In tests the new wet-chemical tool operated with a breakage rate of no more than 0.1 percent, including automation. Due to a magnetic coupling system the gear wheels and drives are completely separated from the wet chemical bath. The new IPSG CEI 4800 is built following a modular concept which allows easy maintainability and accessibility to all modules and components. This results in a higher uptime and an outstanding process performance-to-price ratio.

The machine will be sold in a bundle with the Manz SpeedPicker, a proven automation tool for loading and unloading. The IPSG CEI 4800 will be produced in Manz’ new Suzhou fab which was opened in a grand ceremony last week. This new fab will provide German quality at local prices on 16,000 square metres of factory space, based on the company’s 20 years experience in wet-chemical processes for printed circuit boards (PCB) and flat-panel displays (FPD). Manz will follow up in its drive to become a full-process PV equipment supplier with new vacuum coating equipment and a new texturing tool soon.

PSG removal process: Removal of the remaining PSG layer on the front side of the wafer.